Standby Diesel Generator Set

1. Standby genset for emergency use

In order to ensure the reliability of the power supply, some important users such as hospitals, data centers, and communication hubs, set the dual power supply in their power supply systems. In addition, they also have an emergency generator inside, and some even have an uninterrupted power supply (UPS) for ensuring uninterrupted power supply to some important places and equipment in an emergency.

The standby generator will only be started automatically when the main grid fails and the dual power supply is powered off at the same time. Some important users purchase standby generators just for emergencies. Although these generators are normally stationary, in order to be able to start and generate electricity in an emergency, it usually takes a lot of manpower and material resources to maintain them carefully.

2. Standby generator set principle

2.1 Power selection

Calculate the different loads, and select the generator according to the needs.

2.2 Engine selection

Generally, a diesel generator should be installed and will be used as standby power supply and emergency power supply at this time.

2.3 Generator selection

2.3.1 Selection of the quantity of units. When selecting the capacity of the generator by the starting capacity of the loads, the quantity of generator should not be too many. Because the quantity of units increases, but the single unit capacity is small, it may not meet the starting requirements of the loads. Generally, when the loads do not exceed 800kW, it is better to choose a single machine. When the loads are above 800kW, 2 units should be selected, and the various physical parameters of the 2 units should be the same, which is convenient for the units to work in paralleling.

2.3.2 Selection of functions. High-speed diesel generator and brushless automatic excitation alternators should be installed for standby emergency generator in civil buildings. The generator should be equipped with fast auto starting control system and ATS automatic transfer switch for power transfer between main grid and generator, and should have the function of three consecutive self-starting. Compressed air should not be used for starting, and a 24V battery pack is generally used as the starting power source.

2.4 Self-start

The diesel generator equipped with auto start control system and ATS can start quickly when the mains power is cut off. And automatically switch off with the mains terminal to send electricity. When the mains power comes in, the switch will automatically switch to the mains power. It has the advantage of high sensitivity and good safety.

The starting type is closely related to starting current. Different starting types have large differences in starting current. The usual start-up types are: direct start, star-delta start, step-down start, soft start and variable frequency start.

The starting current of the direct starting mode is the largest, and the starting current of the star-delta starting is about 1/3 of the starting current of the direct starting. The starting current of the step-down starting is related to the starting voltage. Compared with the direct starting, the starting current ratio is the ratio of the square of the step-down voltage to the square of the direct starting voltage (I1/I2=U12/U22). Different soft-starts have different soft-start currents, which are usually 1 to 3 times the rated running current. The starting current of variable frequency starting is the smallest.

For selecting a large power standby diesel generator, it should consider an appropriate starting type according to the direct starting current of the generator and the SKVA value under this voltage requirement.

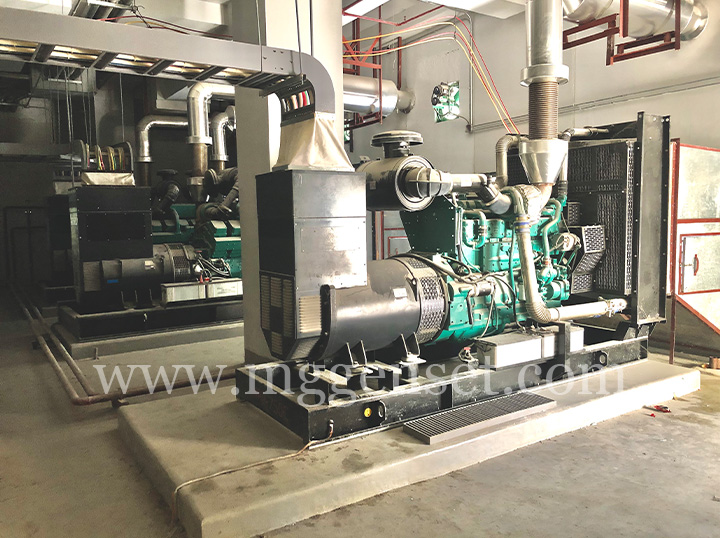

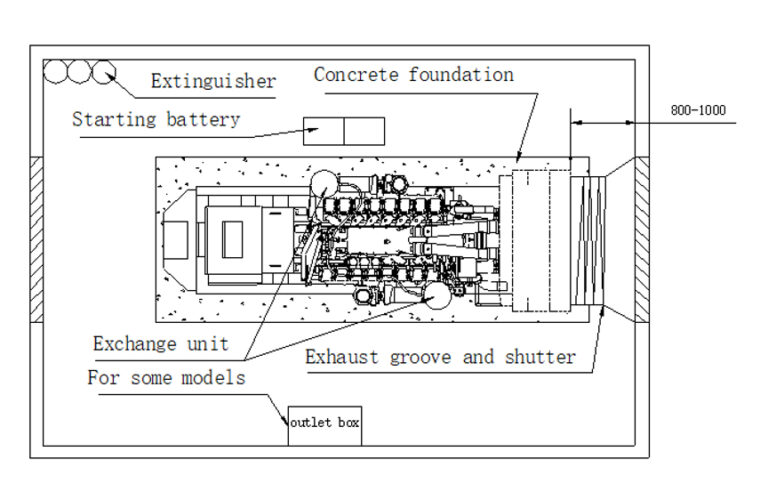

2.5 Location selection

The machine room should be close to the transformation and distribution room as much as possible, because it is convenient for wiring, reducing the loss of materials and electric energy, and also easy to manage. If conditions permit, it is better to set the machine room on the first floor, which is convenient for ventilation, heat dissipation and smoke exhaust. However, in high-rise buildings and large and medium-sized commercial buildings, the first floor is usually used as a commercial area, and the owners generally do not agree with this plan and often set up the machine room in the basement.

The machine room should have one side against the outer wall for better ventilation and exhaust of the generator. Attention should be paid to the ease of lifting, handling and maintenance of the generator. Normally the access channel of the parking area is used as the handling channel, but if the channel is too small, the lifting should be considered. The location of the machine room should avoid damp places, and should not be located under or next to places such as toilets, bathrooms, and pools, so as to avoid affecting the operation of the generator due to toilet maintenance or water seepage from the floor.

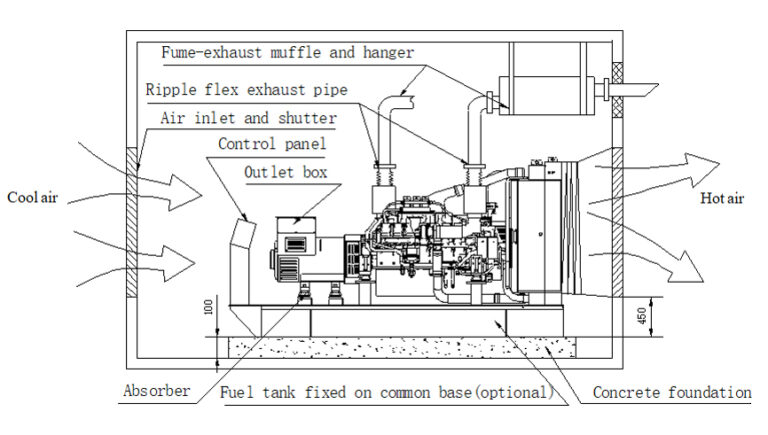

2.6 Ventilation and heat dissipation of the unit

Diesel engine, generator and exhaust pipe all emit heat during operation, which increases the temperature of the machine room. If the temperature rises to a certain extent, it will affect the output of the generator. Therefore, it is very important to ensure the cooling of the generator. When there are enough air intake and exhaust passages, a closed water circulation and air-cooled integral generator is generally used. Otherwise, the exhaust fan and the cooling pipe can be separated from the main body of the generator and placed outdoors separately, and the outdoor heat dissipation can be dissipated by water pipes. The pipe is connected to the diesel engine.

2.7 Nose treatment

The generator for civil buildings are high-speed units with relatively large noise. In order to meet the environmental protection requirements, sound-absorbing materials and noise reduction measures should be installed in the machine room. As the actual situation of each project is very different, it needs to make the applicable solution according to the specification requirements from end users and the actual situation on site.

3. Routine maintenance and testing of standby generator

Note: Test the backup generator regularly, but don’t just run it with no or light load.

3.1 Test with no load or light load

Gradually add up the load and balance at full rated load. Avoid operation with no load or light load. If your schedule includes weekly or monthly operation at no load or light load, the operating period should be limited to minutes or until the battery charge rate returns to normal.

On engines with light load characteristics, we recommend regularly analyzing fuel and oil samples and changing the fuel and oil accordingly. This will help detect excessive fuel dilution and general oil deterioration and avoid premature wear of engine components.

If you experience a start/stop failure event, please contact your local dealer. Make sure to complete a thorough inspection, especially checking the exhaust system for unburned fuel and drain accordingly. After that, it should run at full load for at least four hours.

3.2 Test under full load

It’s a good idea to set up a regular schedule to run the engine at full load for at least four hours. This will keep the battery in good working condition, burn off any carbon that has built up in the engine and exhaust system, and allow your technical team to practice the process of switching back to mains power after the generator is in use. The load should be built up gradually from zero within the first hour and balanced at full rated load.